[ad_1]

Chinese language researchers have developed a brand new passivation method for shingled photo voltaic panels based mostly on tunnel oxide passivated contacts (TOPCon) or heterojunction (HJT) tech. This reduces recombination loss within the cell-to-module course of and is reported to extend open-circuit voltage, fill issue, and effectivity.

Researchers led by Hebei College in China have developed a low-temperature, non-vacuum, large-area spray passivation method to compensate for the lack of effectivity brought on by the chopping and separation course of within the manufacturing of shingled photo voltaic panels. panel based mostly on TOPCon and HJT expertise.

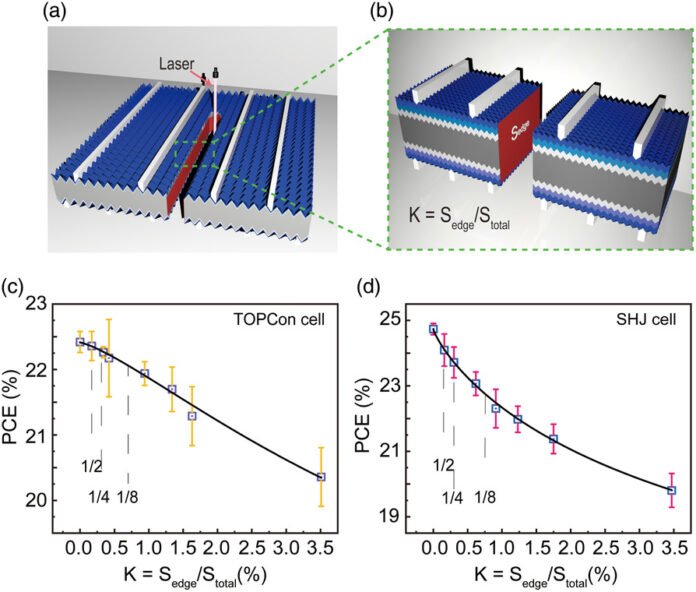

The teachers defined that the losses are brought on by combining the strips of the shingled panels within the cell-to-module (CTM) course of, for the reason that photo voltaic cells should be minimize into a number of subcells by means of a single course of. in laser writing that leaves unmodified internal edges, which in flip leads to decreased effectivity attributable to recombination.

“To compensate for this recombination loss in the course of the CTM course of, we used an natural polymer ink blended with ethanol, water and Nafion to type the passivation layer,” stated the scientists. “We present that the natural passivation coating can cut back the newly fashioned loss edge from laser writing.”

Stated methodology of spraying can produce a uniform movie on the passive facet in comparison with the one with out.

“Photo voltaic cells with a passivation layer are brighter than these with out. This reveals that the natural passivation layer has a wonderful edge passivation impact for TOPCon and SHJ photo voltaic cells and the sting recombination losses are largely decreased, “they stated, including that the passivation layer considerably will increase the open-circuit voltage and fill issue of the cells. .

They discovered that the method can improve the fill issue of a 24.4%-efficient HJT machine from 77.9% to 82.5%, with the effectivity itself rising by 1% to 2%.

“The machine can obtain long-term stability by means of cautious humidity management and easy packaging expertise,” additionally they stated.

The scientists launched a brand new method in “Compensating Chopping Losses by Passivation Answer for Trade Upgradation of TOPCon and SHJ Photo voltaic Cells,” which was not too long ago printed in Superior Vitality & Sustainability Analysis. The analysis crew additionally contains scientists from the Chinese language module maker Yingli Inexperienced Vitality Holding Co., Ltd. and the Quzhou Inexperienced Trade Clustering Zone.

“This simple and non-vacuum methodology is appropriate with present manufacturing traces and might be immediately utilized to industrial silicon photo voltaic cells sooner or later,” they concluded.

This content material is protected by copyright and is probably not reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link