[ad_1]

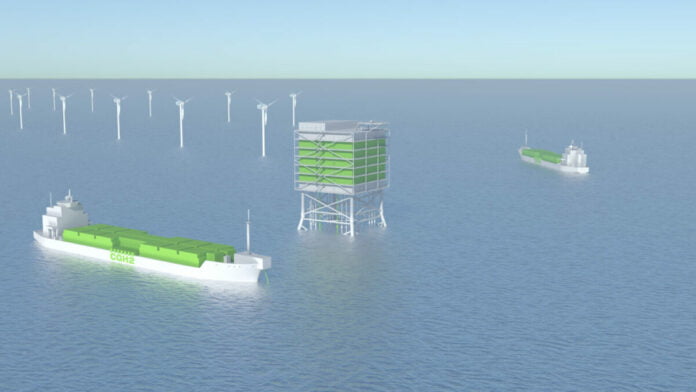

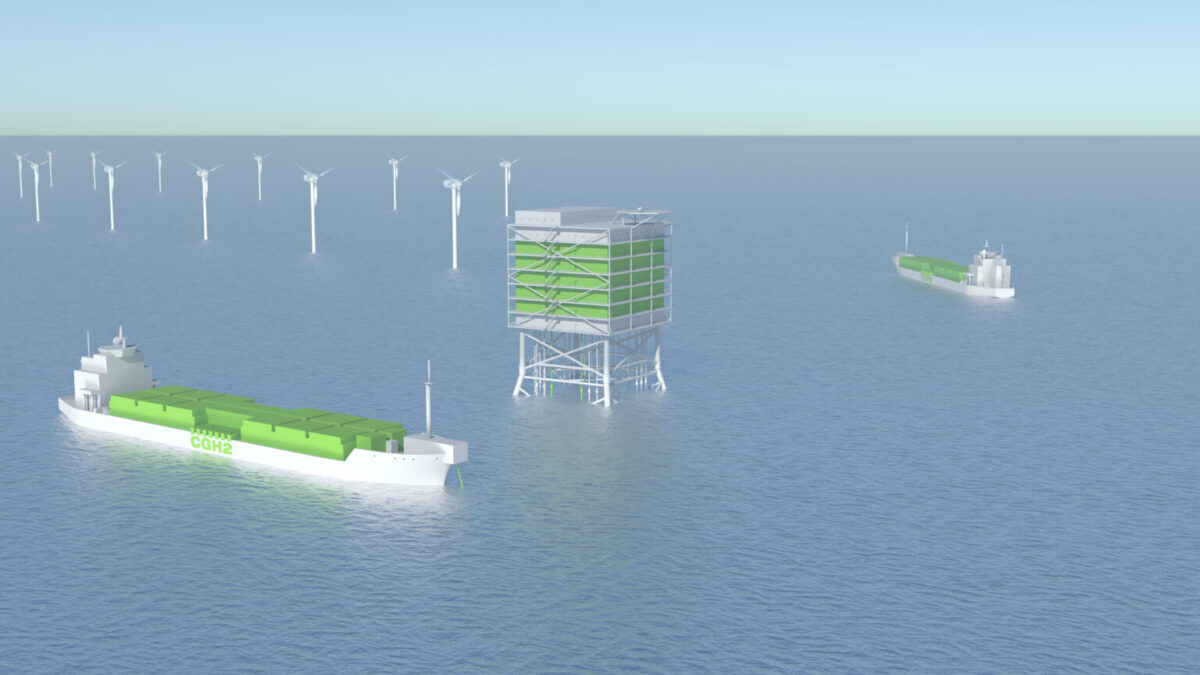

Scientists from the Fraunhofer Institute for Photo voltaic Power Techniques ISE have developed a technical idea and design for a hydrogen era plant optimized for marine use. The “OffsH2ore” mission goals to outline a technically and economically optimized design for an built-in offshore hydrogen manufacturing plant utilizing proton alternate membrane (PEM) electrolysis, together with the transport of compressed hydrogen fuel to land.

The ability provide for electrolysis comes from an offshore wind farm immediately linked to the five hundred MW electrolysis platform. The platform can produce as much as 50,000 tons of inexperienced hydrogen per yr. Recent water for the PEM electrolyser is obtained by desalinating seawater utilizing residual warmth from electrolysis.

The produced hydrogen is purified and dried, compressed to 500 bar, and transferred to a transport vessel that may carry as much as 400 tons of hydrogen from the platform to the mainland. This idea is impartial of the hydrogen transport pipeline and affords flexibility within the selection of location.

“The outcomes present that the manufacturing of hydrogen immediately within the sea with a PEM electrolyzer is technically and economically possible,” defined the scientists.

The mission is funded by the German Federal Ministry for Financial Affairs and Local weather Safety.

“With the idea offered by the consortium, fast and large-scale implementation is real looking,” the researchers mentioned.

The idea ensures the manufacturing of hydrogen with out territorial competitors.

“Offshore hydrogen manufacturing affords the chance to cowl the whole worth chain on the nationwide degree whereas breaking the enlargement of offshore wind energy and the enlargement of the grid,” mentioned Marius Holst, the mission coordinator.

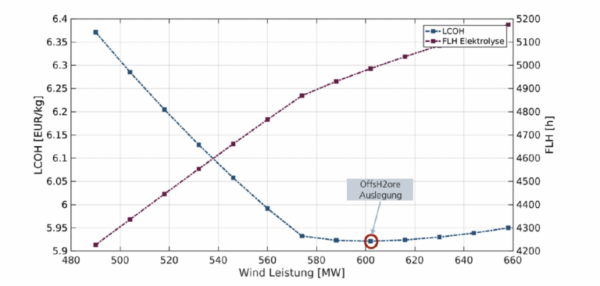

To find out the price of hydrogen manufacturing, step one is to find out the cost-optimal capability of the offshore wind farm based mostly on the electrolysis capability of 500 MW. The minimal price of hydrogen manufacturing outcomes from wind energy of 602 MW. On this case, they quantity to five.92 EUR/kg which is just below 5,000 hours of full cost of electrolysis.

Hydrogen manufacturing prices enhance and full cost occasions lower with decrease air capability. For instance, a wind farm with a capability of 490 MW ends in hydrogen manufacturing prices of €6.37 ($7.04)/kg and full load hours of about 4,225 h/a. On account of the low wind capability, the five hundred MW electrolysis is just too giant and can’t function at a nominal load.

The consortium engaged on the mission consists of Fraunhofer ISE, PNE AG as mission coordinator, SILICA Verfahrenstechnik GmbH, KONGSTEIN GmbH, and Wystrach GmbH.

Scientists from the College of Adelaide in Australia have lately found a solution to produce hydrogen immediately from untreated seawater. For this, they launched an acid layer of catalysts in situ.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link