[ad_1]

US scientists have developed a monocrystalline photo voltaic panel that depends on “minicells” based mostly on polysilicon with silicon oxide passivating contacts. The module works with laser gentle and is reported to attain a photoconversion effectivity of greater than 40% and an open-circuit voltage of seven V.

A gaggle of scientists led by the US Division of Vitality Nationwide Renewable Vitality Laboratory (NREL) designed a monocrystalline mini photo voltaic panel that may convert laser gentle into electrical energy.

“This know-how is cheap as a result of it’s based mostly on silicon and makes use of the identical processes used for terrestrial cells as TOPCon gadgets that depend on silicon oxide passivating contacts,” the lead writer of analysis, Paul Stradins, mentioned. pv journal. “The module consists of poly-Si / SiO2 passivated contact minicells. These minicells supply very low contact resistance, which is appropriate for lengthy operation within the solar.

on paper”Excessive voltage monocrystalline Si photovoltaic minimodules based mostly on poly-Si/SiOx passivating contacts for high-power laser energy conversion,” revealed in Photo voltaic Vitality Supplies and Photo voltaic Cells, the scientists defined that the panel could possibly be used, for instance, in purposes comparable to wi-fi information transmission in particular environments or vitality transmission in medical implants, and so forth.

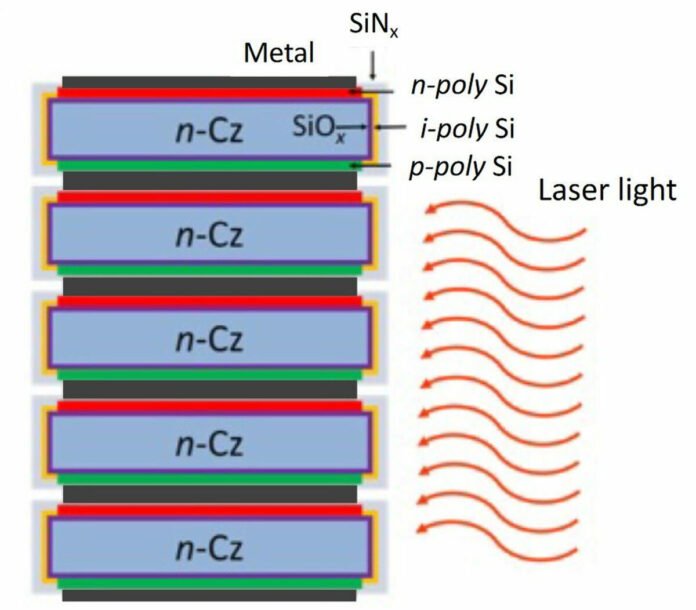

The multijunction mini panel is designed with silicon oxide (poly-Si/SiOx) passivated contacts utilizing a really skinny SiOx layer of roughly 1.5 nm. These passivated contacts are used to make minicells that reportedly supply extraordinarily low contact resistance, appropriate for long-day operation. The minicells are positioned “on the sting” and packaged in modules.

“These minicells could be composed into micromodules by mechanical stacking,” mentioned Stradins. “We used 10 cells, but it surely could possibly be any quantity. Subsequently, the voltages of those micromodules shall be excessive, whereas the currents will stay low.

In a photo voltaic module, direct metallic contact from one cell to the following permits electrical energy to circulation freely between them, with a big contact space that limits collection resistance. Gentle is absorbed vertically by means of the slim fringe of the system and present is collected laterally by means of massive space p- and n-type passivating contacts.

In line with the researchers, this structure permits the present cell to be collected in all the “facet” space of a minicell, which is bigger than the sunshine entry space. “These 10- or extra minicell stacks could be assembled into any measurement bigger energy beaming conversion module,” Stradins additional defined. “No measurement restrict, could be meters if wanted, with cooling, tabbing, and energy electronics on the again.”

The analysis group examined the module in an illumination round 1000 nm and located the photoconversion effectivity exceeded 40% and the open-circuit voltage exceeded 7 V. The fill issue was near 78 %. “Based mostly on the present outcomes of the system, it’s anticipated {that a} energy switch of 25 W could be obtained for a ten cm2 module with a 12 kW laser supply at a distance of 1 km,” the teachers mentioned.

In line with Stradins, the minicells are made with none costly lithography. “We use mechanically aligned masks for all deposition steps, that are simply created with an ns laser scriber,” he mentioned. “The minicells are additionally produced in the identical course of because the laser scriber. They continue to be connected to the wafer and are processed as a complete wafer, for all steps together with the ultimate metallization. Solely then are they separated and assembled in a micromodule.All this may be automated in a manufacturing line.

This content material is protected by copyright and is probably not reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link