[ad_1]

A Spanish-Finnish analysis crew has developed an IBC photo voltaic cell with an ultrathin black silicon wafer with a thickness of 40 µm. The machine relies on vanadium oxide and laser-processed phosphorus-doped silicon carbide stacks as gap and electron transport layers, respectively.

A global analysis group goals to make use of black silicon (bSi) to provide ultra-thin substrates for purposes in interdigitated back-contact (IBC) photo voltaic cells.

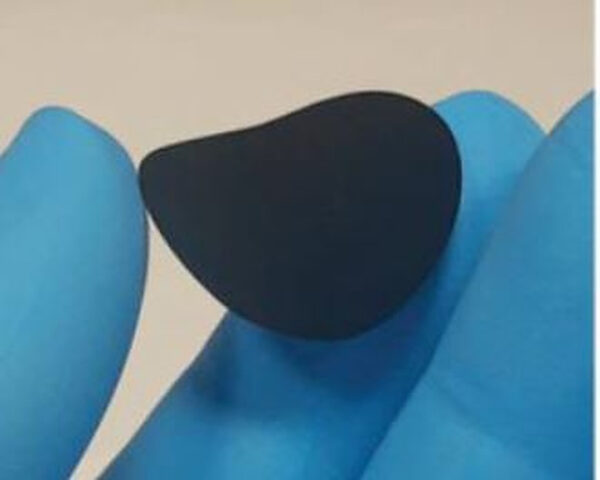

This sort of silicon gives the benefit of allows the manufacturing of ultrathin and versatile wafers with low ranges of impurities, leading to distinctive light-absorbing properties and low manufacturing prices. “Black silicon is a random nanotexture that reduces floor reflection from all instructions to a minimal, in order that Si turns into eye-black versus the standard micron-scale random pyramids,” defined the scientists.

Picture: Polytechnic College of Catalonia, Nano-Micro Small, Artistic Commons License CC BY 4.0

They used deep reactive ion etching (DRIE) at cryogenic temperatures to provide Si substrates with totally different thicknesses as much as 10 µm. This course of is a plasma-based etching technique that gives deep holes and trenches with steep edges on silicon wafers.

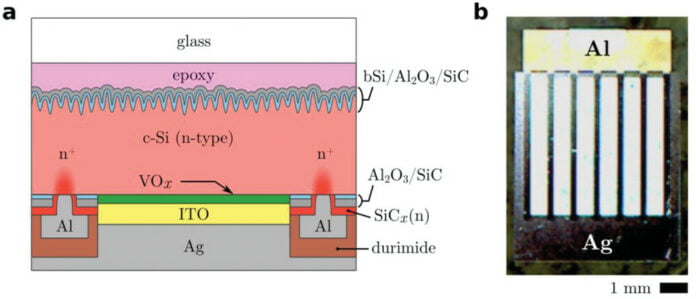

The researchers used a Si substrate with a thickness of 40 µm to construct a photo voltaic cell with an IBC structure, which they are saying can reap the benefits of the optical benefit of a bSi entrance floor. of the fabric. “The IBC c-Si photo voltaic cell construction used relies on vanadium oxide (VOx) and laser processed phosphorus-doped silicon carbide stacks as gap and electron transport layers, respectively,” they defined.

The cells additionally depend on a floor passivation layer product of aluminum oxide (Al2or3) and silicon carbide (SiC). “We selected a conformal Al2or3 layer deposited by atomic layer deposition (ALD) as a result of it gives wonderful floor passivation of the bSi nanotexture, reaching a mean lifetime of greater than 250 µm on our bSi ultra-thin wafers,” mentioned the scientist.

The PV machine achieved an influence conversion effectivity of 16.4%, open-circuit voltage of 633 mV, short-circuit present density of 35.4 mA cm-2 , and a fill issue of 73.4%. For comparability, a reference cell with a cultured entrance floor and with out the black silicon wafer achieved an effectivity of 11.5%, an open-circuit voltage of 600 mV, a short-circuit present density of 27.1 mA cm.-2and a fill issue of 70.7%.

“Exterior Quantum Effectivity (Stroll) outcomes with a bSi entrance floor outperform the identical machine with a cultured entrance floor in all measured spectrum ranges, from close to infrared (NIR) to ultraviolet (UV), exhibiting that the optical properties could be efficiently transferred to {the electrical} photovoltaic efficiency of a closing, encapsulated, cell,” the scientists concluded, noting that additional work is required to enhance the effectivity of the entrance mild seize. that bSi texture.

They offered new wafer and cell know-how within the paper “Black Extremely-Skinny Crystalline Silicon Wafers Attain the 4n2 Absorption Limitation–Utilization of IBC Photo voltaic Cells,” printed in Nano-Micro Small. The analysis crew consists of teachers from Polytechnic College of Catalonia in Spain and the Aalto College in Finland.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link