[ad_1]

US engineers have constructed a scalable thermal power storage prototype system that mixes optimum latent and rational warmth switch. The know-how, which is now prepared for the market after three years of testing, consists of engineered cementitious supplies and thermosiphons in a mixture that allows quick, environment friendly thermal efficiency at low prices.

Thermal power storage programs use temperature adjustments to retailer power for later use, or to be used at different places. Probably the most generally used strategies of power extraction are primarily based on latent and wise warmth switch.

The previous warmth technique makes use of the quantity of warmth power required for a section change – that could be a change in bodily state, akin to from stable to liquid, or liquid to gasoline. – with out altering the temperature of a fabric. This method is related to giant power densities. The latter is the warmth power required to lift the temperature of a fabric with out inflicting any section transitions. A serious benefit of this technique of warmth switch is the low price.

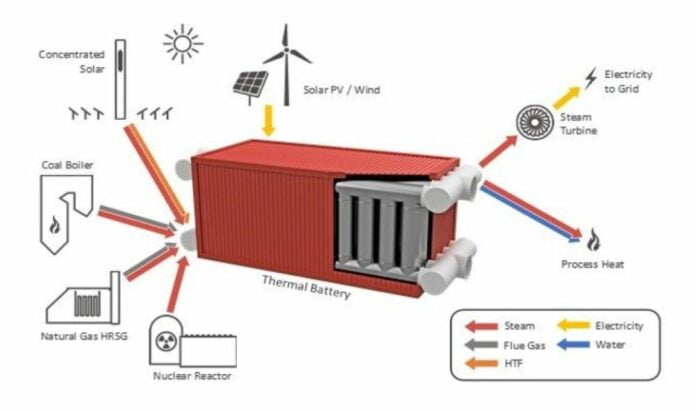

Now, engineers at Lehigh College in Pennsylvania, with help from the US Division of Vitality, have developed a brand new thermal power system that mixes the perfect of each methods. The Lehigh Thermal Battery consists of engineered cementitious supplies and thermosiphons together that allow quick, environment friendly thermal efficiency at low price. The know-how can work with warmth or electrical energy because the charging power enter.

The group introduced that, after three years of analysis and growth, the Lehigh Thermal Battery is prepared for the market. The method consists of built-in system testing of three, 10 and 150 kilowatt-hours thermal (kWhth) in a related setting.

The 150-kWhth prototype constructed by the Vitality Analysis Heart is an entire instrumented construction containing 22 finned thermosyphons. The 150-kWhth prototype has been extensively examined utilizing compressed air at 480 C, producing an energy-to-energy cost/discharge effectivity in stable media of greater than 95%, uniform temperature distribution in stable media throughout charging, and fixed cyclic reversibility.

The typical energy charges achieved throughout charging and discharging are 16.4 kWth and 19.8 kWth, respectively, with a really robust thermal battery power gradient of 0.51 kWhth/min within the first hour of unloading.

Co-principal investigator Sudhakar Neti, professor emeritus in Lehigh’s Division of Mechanics and Mechanical Engineering, says the know-how is progressive on many ranges.

“It’s modular, designed for impartial power enter / output stream throughout charging / discharging, which is feasible with the assistance of thermosyphons, and the two-phase course of of adjusting the contents of the thermosyphon tubes permit speedy isothermal warmth switch to / from the storage media. at very excessive warmth switch coefficients and warmth charges,” stated Neti.

Carlos Romero, co-principal investigator of the undertaking and the director of the Vitality Analysis Heart at Lehigh, stated that the concrete plus thermosiphon idea is exclusive among the many warmth power storage idea.

“The know-how provides the potential for adaptation to a variety of temperatures, and warmth switch media and working situations,” stated Romero.

These qualities make the Lehigh Thermal Battery appropriate for decarbonization alternatives in energy-intensive industrial sectors, the pliability of typical energy crops, and the event and penetration of concentrated solar energy.

“One other alternative for Lehigh Thermal Battery to play an vital function within the decarbonization effort is to mix thermal power storage with a system that features warmth pumps and Natural Rankine Cycles, which work with surplus renewable electrical energy. ,” Neti stated.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link