[ad_1]

Summary:

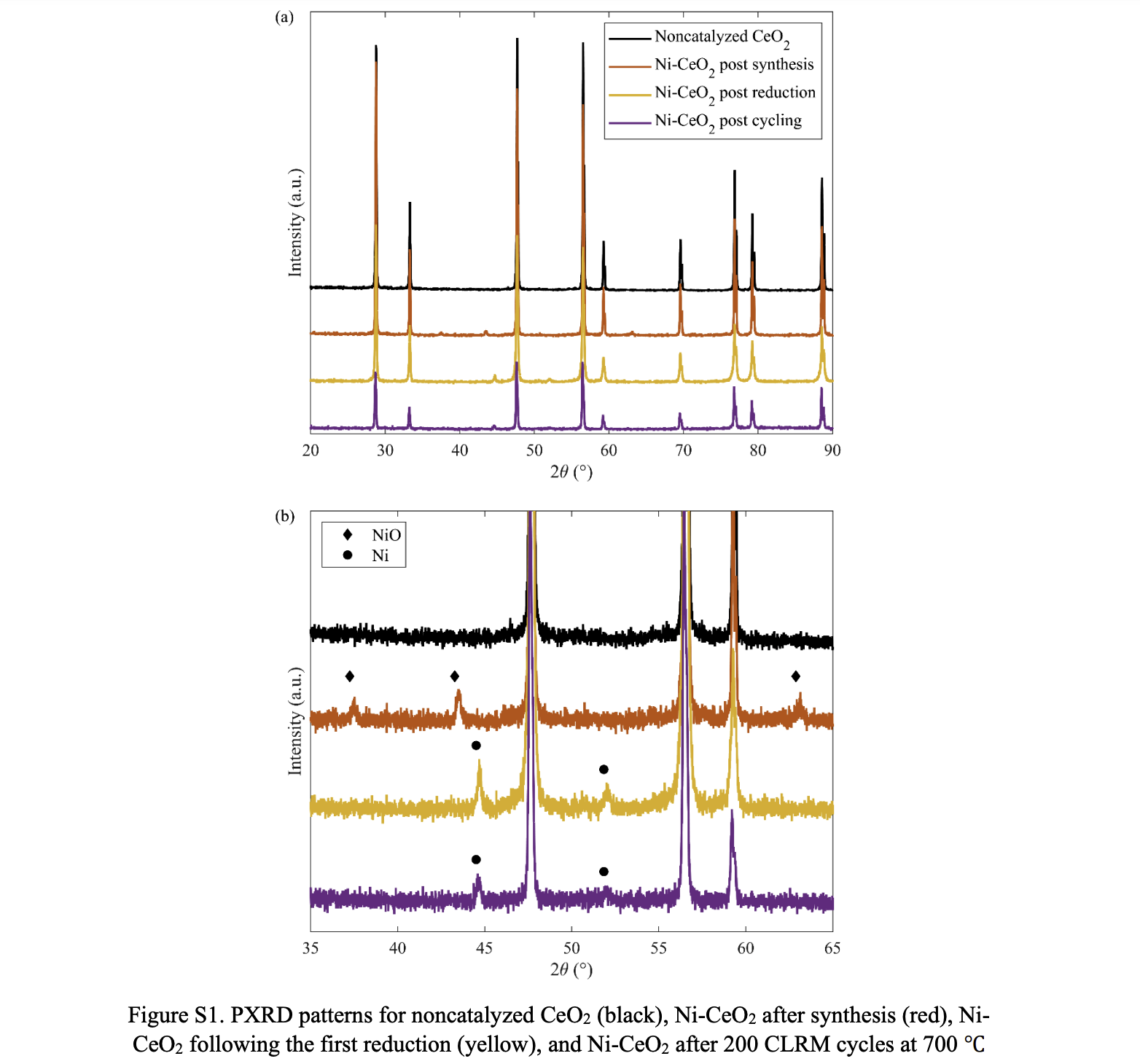

The usage of photo voltaic thermal power to drive the chemical looping reforming of methane (CLRM) is a promising option to effectively and selectively reform methane to supply syngas utilizing renewable power. On this work, the position of catalytically lively nickel in response kinetics, conversion, selectivity, and complete syngas manufacturing throughout CLRM of Ni-CeO2 investigated. By way of thermogravimetric evaluation (TGA), metallic nickel was proven to assist enhance the partial oxidation of methane (POM) response charges because of the decrease activation power response mechanism in all oxygen nonstoichiometries, in comparison with CeO2. For instance, the discount fee of Ni-CeO2 at 700 °C is akin to CeO2 at 900 °C, and no response was noticed for CeO2 at 700 °C. Moreover, prolonged biking with Ni-CeO2 confirmed steady response charges and yields throughout CLRM at 700 °C, and SCo remained above 0.98 in the course of the experiment. The usage of a bigger packed-bed reactor system, Ni-CeO2 additionally confirmed related methane conversion, syngas manufacturing and selectivity to CeO2however at a lot decrease working temperatures, ie, Q ≤ 800 °C. A better fee of coking was noticed through the POM of Ni-CeO2; nonetheless, all carbon was eliminated within the subsequent step and accumulation was not noticed throughout long-term biking. A parametric research of fuel velocity, temperature, and inlet partial stress of methane can also be offered to evaluate the impact of those working circumstances on the conversion, choice, and manufacturing of syngas. Notably, a tradeoff between the conversion and the quantity of syngas produced was noticed because the fuel velocity elevated; nonetheless, the conversion time response signifies that there’s a really perfect response cut-off time the place excessive syngas manufacturing charges might be concurrently achieved with near-complete methane conversion.

[ad_2]

Source link