[ad_1]

The NREL researchers used an acoustically spalled gallium arsenide substrate that reportedly reduces electrical shunting, leading to probably decrease manufacturing prices. The cell achieved an open-circuit voltage of 1.061 V, a short-circuit present density of 29.9 mA/cm2, and a filling issue of 84.9%.

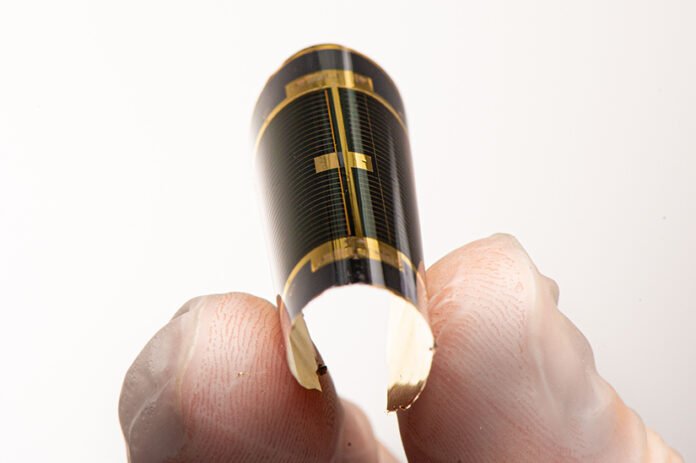

Researchers on the US Division of Power’s Nationwide Renewable Power Laboratory have developed a III-V gallium arsenide (GaAs) photo voltaic cell primarily based on a substrate made from spalled GaAs.

The price of making photo voltaic cells primarily based on compounds of III-V materials components, named in accordance with the teams of the periodic desk they belong to, restricts these units to area of interest purposes, corresponding to drones and satellites, the place low weight and excessive effectivity are extra necessary issues than the price of the vitality produced.

“Reducing the price of manufacturing is taken into account the important thing to soil purposes, and a method to do that is to have the power to repeatedly use the substrate on which the cells are grown,” stated the researchers. That is the motivation for the event of acoustic spalling, a brand new course of that they declare represents a low-cost reuse pathway for III-V epitaxial development substrates with restoration and reuse of the substrate.

Within the paper “GaAs photo voltaic cells grown on acoustically spalled GaAs substrates with 27% effectivity,” not too long ago revealed in JouleThe researchers defined that acoustic spalling, also referred to as sonic lift-off (SLO), is an experimental course of that makes use of sound waves to regulate the propagation of the crack tip throughout spall to forestall aspect formation and enhance floor flatness.

“Present know-how makes use of a sacrificial etch layer, which permits a cell to be faraway from a gallium arsenide (GaAs) substrate in order that the substrate could be reused, however the course of takes hours and leaves a residue that requires a sharpening step,” defined the group. “Sprucing is comparatively costly and limits the potential price financial savings of this methodology of reusing the substrate. In distinction, spalling takes seconds, which creates a managed fracture inside the substrate virtually parallel to its floor. This fracture permits the cell to be simply eliminated, revealing a brand new, uncontaminated floor from inside the substrate with out the necessity for sharpening.

The lecturers constructed PV units with a nip construction and a 1 mm-thick emitter made from GaAs and selenium (SE), a 1 mm unintentionally doped GaAs layer, and a 1 mm base layer made from GaAs and zinc (Zn) on an as-spalled SLO substrate with out moist etching.

Examined beneath normal lighting circumstances, the champion system manufactured with this structure achieved a licensed energy conversion effectivity of 26.9%, an open-circuit voltage of 1.061 V, a short-circuit present of 29.9 mA/cm2, and a fill issue of 84.9%, with the cell displaying no indicators of non-linear shunting. reduces the present flowing within the photo voltaic cell junction and reduces the voltage from the photo voltaic cell.

“These outcomes allow the event of epitaxial high-performance units on probably lower-cost substrates with mm-scale options,” the researchers stated, including that the acoustic spalling used for the development of the cells was developed at Arizona State College and is now commercialized by Phonenix-based startup Crystal Sonic Inc.

In July 2022, different researchers from NREL developed a III-V photo voltaic cell primarily based on a substrate made from spalled germanium (Ge). They used spalled Ge as an alternative of gallium arsenide (GaAs), as a result of the previous, generally utilized in house purposes, reportedly reduces most of the spalling-related problems with GaAs.

This photo voltaic cell was capable of obtain an influence conversion effectivity of 23.36% the place there aren’t any spalling defects. It additionally achieves an open-circuit voltage of 1.019 V, a short-circuit present density of 28.49 mA cm-2, and a fill issue of 80.45%. In accordance with the scientists, these outcomes present that spalled germanium doesn’t have to be restored to a clear, polished state to realize high-quality system efficiency.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link