[ad_1]

As a substitute of utilizing photo voltaic or wind to energy electrolysis, researchers are testing competing photoelectrochemical cells to supply hydrogen fuels with out emissions.

From pv journal USA

“Inexperienced” hydrogen is the manufacturing of hydrogen fuels utilizing sources of free technology equivalent to photo voltaic and wind energy. Whereas renewable-charged battery-powered autos and energy crops are anticipated to make up a big a part of the power transition, inexperienced hydrogen is gaining curiosity for heavy-duty vehicles and circumstances of business use because of its capability to transmit excessive quantities of energy.

The manufacturing of inexperienced hydrogen often takes the “oblique” methodology utilizing photo voltaic and wind in electrolyzers. These electrolyzers obtain effectivity of round 30%.

A analysis group on the Helmholtz-Zentrum Berlin (HZB) Institute for Photo voltaic Fuels is investigating one other path to emission-free hydrogen manufacturing by means of a course of they name the “direct” methodology. The tactic is PROVIDED not too long ago Communication in Nature article.

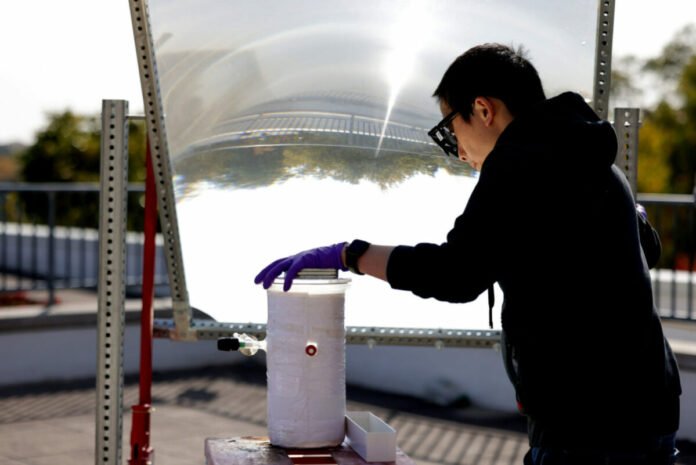

The workforce developed photoelectrodes that convert daylight into electrical power, are secure in aqueous options, and catalytically break up water into hydrogen. Photoelectrodes are mixed with catalyst supplies, which create the energetic element of a photoelectrochemical (PEC) cell.

Right now, the perfect PEC cells can obtain efficiencies near 10% and are manufactured from low-cost and comparatively secure steel oxide absorbers. Though they’re much less environment friendly than their oblique inexperienced hydrogen counterparts, PEC cells have some benefits. Warmth from direct daylight can be utilized to hurry up reactions. And, because the densities are ten to 100 instances decrease on this methodology, extra and cheaper supplies can be utilized as catalysts, stated the researchers.

Regardless of these promising parts of the PEC method, the techno-economic evaluation and internet power evaluation present that it’s not but aggressive with the traditional inexperienced hydrogen manufacturing method. Hydrogen gas from PEC methods prices about per kg, about six instances greater than “blue” hydrogen from fossil methane steam reforming at .50 per kg. Additionally, the cumulative power demand for PEC water splitting is estimated to be 4 to twenty instances increased than for hydrogen manufacturing with renewable power and electrolyzers.

Regardless of this gulf in price effectiveness between the strategies, the HZB Institute analysis workforce is testing different potential advantages of PEC. The workforce examined the consequences of how hydrogen produced additional reacts with itaconic acid in the identical reactor to kind methyl succinic acid (MSA). MSA is one other chemical gas that can be utilized to move giant quantities of power equivalent to hydrogen.

PEC expertise permits MSA to be produced at solely one-seventh of the standard power necessities of MSA gas manufacturing processes.

To search out out, the researchers calculated how a lot power is required to make the PEC cell from gentle absorbers, catalyst supplies and different supplies equivalent to glass, and the way lengthy the system must function so as to this power will be within the type of chemical power equivalent to hydrogen or MSA. .

For hydrogen alone, the power payback interval is about 17 years when contemplating a median 5% solar-to-hydrogen effectivity. If solely 2% of the hydrogen produced is used to transform itatonic acid to MSA, the power payback time is halved. If 30% of the hydrogen is transformed to MSA, the manufacturing power will be recovered after 2 years.

“This makes the method extra sustainable and aggressive,” stated Dr Fatwa Abdi, HZB Institute for Photo voltaic Fuels. “This methodology gives a method to scale back the price of inexperienced hydrogen manufacturing and improve the financial feasibility of PEC expertise. We’ve thought fastidiously in regards to the course of, and the subsequent step is to check within the laboratory how the simultaneous manufacturing of hydrogen and MSA is sweet in apply.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link