from pv journal in Australia

Australian Nationwide College (ANU) spinoff Syenta has simply accomplished a $2.46 million seed funding elevate to assist ship its 3D electronics printers to its first clients. After engaged on the product for the previous three years, co-founder and CEO Jekaterina Viktorova mentioned pv journal in Australia the startup will quickly search suggestions on its preliminary printer, which can produce digital prototypes.

“We name it a printer for electronics nevertheless it’s actually only a multi-material 3D print. You are able to do something you need,” mentioned Ben Wilkinson, the pinnacle of analysis and growth. within the Seventy.

Syenta prints utilizing electrochemistry, utilizing a purely additive technique. This technique has the potential to vary manufacturing prices as a consequence of its simplicity, but additionally as a result of the printer makes use of what are primarily major supplies. In different phrases, if somebody needs to print with copper the “ink” is definitely copper sulfate. “Our technique makes the uncooked materials copper as we print it,” Wilkinson mentioned.

“The opposite cool factor about that’s our course of can work in reverse. So we use a voltage to reverse the [for instance] the copper again into copper sulfate, and that turns into a brand new ink that we are able to use once more,” he added. “It is getting nearer to the way it’s finished in biology — the place each useful resource is reusable and it is fully round.”

For Viktorova that’s the fantastic thing about electrochemistry. “It is reversible and it is extra environment friendly in comparison with different strategies.”

Jamie Kidston/ANU

The strategy removes many layers of the method related to conventional manufacturing, thereby decreasing the quantity of each power and supplies that go into manufacturing electronics. It additionally frees applied sciences from their provide chains, which the renewables trade sees as notably beneficial.

The opposite facet of the proposition is what 3D printed electronics can do itself in industries like photo voltaic and battery storage. “We are able to now create rather more refined designs and have these complicated geometries that enhance efficiency for batteries and photo voltaic in addition to scale back prices,” Wilkinson mentioned.

“The geometry of these two applied sciences [solar and batteries] very strongly determines the efficiency. So how far should ions bodily transfer in batteries to cost or discharge? Or, in photo voltaic cells, what’s the resistance of the electrons shifting within the photo voltaic cell? If we are able to do this, just a bit bit, on a nanoscale, we are able to scale back the resistance or the charging time. “

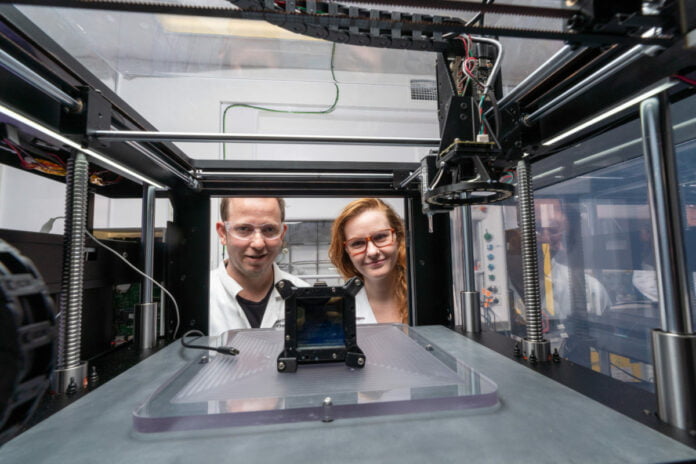

Potential functions apart, Syenta’s present printer — which is targeted on enabling its clients to create expertise prototypes — matches on a desk. “The subsequent step is the precise launch of the product,” says Viktorova. “We’re actively searching for people who find themselves prepared to prototype with our expertise and inform it in our future full product growth exercise, which would be the ultimate product on our web site and transport worldwide.”

In the end, the corporate’s ambition is to focus on large-scale electronics manufacturing. “We expect we are able to do higher than most of the current manufacturing steps for electronics,” Wilkinson mentioned.

“The potential of our expertise could be very excessive in how briskly it may be finished however at present the way in which we do it’s fairly sluggish,” he added. “It is targeted on prototyping however we expect we are able to do giant scale manufacturing and the method is effectively suited to that however there’s lots of engineering that should occur to construct that functionality.”

Till now, the imaginative and prescient of scalable additive manufacturing from 3D printing stays unrealized.

Syenta’s backstory

The core of Syenta’s expertise started with a late-night e-mail between Viktorova and her then PhD supervisor – now co-founder – Professor Luke Connal. The subsequent day on the ANU lab, Viktorova started experimenting.

Whereas many teachers have tried an identical strategy up to now, Viktorova says nobody has finished it in the identical means and, maybe extra importantly, her PhD means she will dedicate years to refining and testing to get it proper.

“The timing and mixture of expertise is correct for us to take it to the following step of commercialization,” he added.

Syenta, which not too long ago modified its identify from Spark3D, is now separate from ANU, though shut collaboration with the college continues.

Additive printing based mostly on electrochemistry

To clarify how the start-up process works, Wilkinson factors to the chrome hubcaps worn on fancy vehicles. That plating, he says, is a type of electrodeposition. “What we do in a different way is that we do not have to make use of chrome, we are able to use many alternative supplies and likewise we are able to print in a really small space. We are able to create complicated patterns with the sort of plating of the fabric.”

When it comes to “additive” element, it refers to a way of merely including supplies. That is completely different from most manufacturing processes, which each add and subtract supplies.

“I believe that is an unimaginable worth proposition in itself,” Viktorova mentioned, referring to the incremental strategy. “You actually don’t have any trash.”

The present Syenta printer primarily prints with metals, together with copper and silver, though it may possibly additionally print gold and nickel. The substrates for the exams are 5 cm x 5 cm, with a printed space of 30 cm x 30 cm.

The printer can create a single-layer printed circuit “in minutes,” says Viktorova, “versus different developed applied sciences that take hours to try this.”

Photo voltaic manufacturing potential

Wilkinson factors to silicon photo voltaic cells and microchips as attention-grabbing methods to assume by means of Syenta’s strategy. Silicon microchips require excessive decision, corresponding to extra complicated patterns in a small area, whereas silicon photo voltaic cells require a lot much less element, making them “low res,” however finished in lots of locations.

“The potential of our expertise is to have the ability to do each of these issues on the identical time – so is the nanoscale, complexity decision of the velocity and space of photo voltaic cells,” Wilkinson mentioned.

Viktrova added that the expertise has “an attention-grabbing relationship between manufacturing precision and velocity – it is fairly linear, which is a uncommon factor to have. That is why we imagine there is a outstanding scalability even in our prototyping which is a product intrinsic to the expertise itself.

Viktorova described photo voltaic as a very attention-grabbing marketplace for Syenta because of the similarity of the arrange; “They simply use completely different expertise [to manufacture] – often additive together with subtractive. So we wish to save this additional step for one individual. “

Environmental results

Producing extra issues usually interprets into extra air pollution. However Wilkinson says that utilizing the emissions scope equation, the scope one emissions from the printer are non-existent – at ANU at the very least the printer runs on renewable electrical energy.

When it comes to scope two, the printer’s additive strategy signifies that no extra supplies are used than crucial. What’s deposited is deposited effectively and quick and in such a means that it may be recycled, that means that every completed, printed product has the least quantity of power it may possibly for its output, he mentioned.

And past these scopes, Wilkinson says that the printer offers folks the power to make higher, cheaper units that improve using renewable expertise, even when it is batteries. , photo voltaic, good units or methods to connect with the Web of Issues. “If it was that low cost, extra folks would undertake it,” Wilkinson mentioned.

The technological innovation half is very essential for startups. “We’re constructing to recycle something we print on the identical product in the identical system,” Viktorova mentioned.

Massive manufacturing

When it comes to the big-picture imaginative and prescient, the Syenta crew thinks their expertise holds lots of promise for large-scale electronics manufacturing, with Wilkinson saying he believes “bulk” electronics manufacturing could possibly be extra effectively utilizing its technique.

Electronics manufacturing is based in Europe, Viktorova mentioned, and this wealthy ecosystem is one thing Syenta hopes to study and study within the close to time period.

“We wish to make a product that sits in current provide chains, or current manufacturing strains which might be sooner and cheaper and have this decision patterning profit,” Wilkinson mentioned. “I am certain it should occur, nevertheless it simply takes effort and time to get that finished.”

It additionally requires a good quantity of sources and financing, one thing the crew is not going to lose. Constructing on the current elevating of seed capital, Viktorova mentioned the corporate will search to boost funds for the following phases of commercialization in 2023.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].