[ad_1]

Scientists have developed a way for creating AZO and i-ZnO/AZO bilayer buildings in photo voltaic cells that tremendously enhance cell effectivity and sturdiness. Utilizing a low energy deposition methodology that avoids elevating the temperature of the substrate, the crew achieved an influence conversion effectivity of 9.53% with good transmission.

A world analysis crew has designed a copper indium gallium diselenide (CIGSe) photo voltaic cell primarily based on an ultrathin aluminum-doped zinc oxide (AZO) movie with sturdy sheet resistance.

“We used a low-power deposition methodology for the manufacturing of AZO and i-ZnO/AZO bilayer buildings used within the cell,” corresponding writer of the analysis, Ganesh Regmi, mentioned. pv journal, indicating that this methodology is meant to enhance cell effectivity and stability. “Through the use of this system, the objective is to keep away from a rise within the temperature of the substrate, which may result in hostile results corresponding to atom implantation into the cadmium sulfide (CdS) layer and potential short-circuiting.”

Scientists say that this system eliminates the necessity for post-deposition remedy, a typical apply in standard strategies that may negatively have an effect on the integrity of photo voltaic cell layers. “In conventional high-efficiency CIGS thin-film photo voltaic cells, a comparatively thick layer of ZnO, with a thickness of 200-300 nm, is commonly used because the window layer,” explains Regmi. “Nonetheless, this strategy limits the pliability of photo voltaic cells, making them unsuitable for some purposes.”

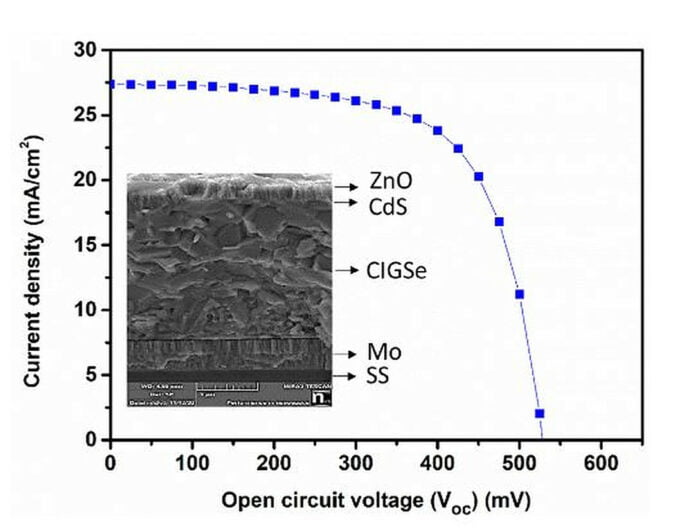

The group constructed the cell utilizing a monolayer product of molybdenum (Mo), the CIGSe absorber, a cadmium sulfide (CdS) buffer layer, a window layer of zinc oxide (i-ZnO), and a zinc oxide (ZnO) movie. The machine achieves an influence conversion effectivity of 9.53%, an open circuit voltage of 530 mV, and short-circuit present density of 27.34 mA/cm2, and a fill issue of 65.78%.

Lecturers declare that AZO movies exhibit good transmission and good crystal morphology, in addition to excellent electrical conductivity. “This outcome confirms the profitable implementation of the proposed strategies and gives proof of the potential of this methodology,” mentioned Regmi.

They describe the research machine “Aluminum-doped zinc oxide (AZO) ultra-thin movies deposited by radio frequency sputtering for versatile Cu(In,Ga)Se2photo voltaic cell,” printed in Recollections – Supplies, Units, Circuits and Methods. The group consists of scientists from the Middle for Analysis and Superior Research of the Nationwide Polytechnic Institute (Cinvestav) in Mexico and Tribhuvan College in Nepal.

This content material is protected by copyright and might not be reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link