[ad_1]

MIT researchers have developed an ultra-thin and ultra-light photo voltaic cell that can be utilized to show nearly any floor right into a supply of solar energy. The versatile photo voltaic cells are thinner than a human hair and glued to a light-weight material to make them simpler to put in on any fastened floor.

“The present model of our new light-weight photovoltaic (PV) cells are usually not as environment friendly at changing electrical energy as silicon PVs, however they weigh much less. Within the quick run, they won’t be used to switch standard silicon PV installations, however to offer energy the place silicon PVs are usually not simply put in,” mentioned Vladimir Bulović, lead creator of the analysis article printed within the journal Small Technique, at indianexpress.com by electronic mail.

“For instance, it may be used to ship photo voltaic electrical energy to hard-to-reach areas. Being 18 instances lighter than silicon PV modules per Watt generated, our PV modules will be simply delivered and put in in distant villages. As our know-how develops, we count on it to achieve the efficiencies at present achieved by silicon PVs. At that time, our versatile PV modules will be thought-about as a substitute for silicon PVs,” added Bulovic.

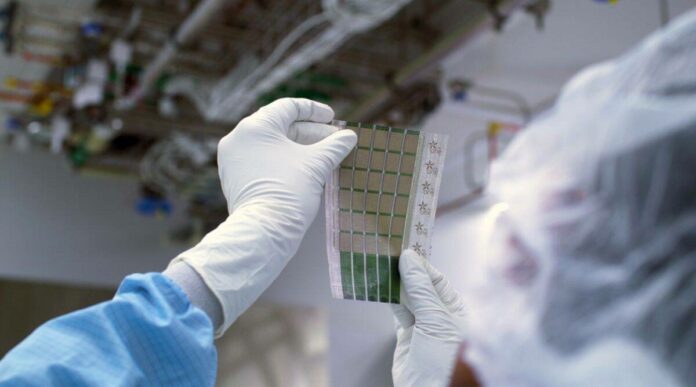

The manufacturing of ultra-thin photo voltaic cells

The researchers used nanomaterials in printable digital inks to create this novel photo voltaic cell gadget. They used a “slot-die coater” to deposit layers of digital supplies on a substrate simply 3 microns thick. They then used a display printing method to print an electrode and deposit a substrate to finish the photo voltaic cell. At this level, the printed module is about 15 microns thick, and the researchers can take away the plastic substrate to take away the gadget. For comparability, human hair is about 70 microns thick on common.

However this ultra-thin freestanding module itself is troublesome to make use of, as it’s simply torn or broken in different methods. To fight this downside, researchers turned to a cloth recognized commercially as Dyneema – a particular kind of cloth that makes use of solely 13 grams per sq. meter.

In keeping with MIT, the textile fibers are so robust that these ropes had been used to elevate a sunken cruise ship from the underside of the Mediterranean sea. They adhere the photo voltaic gadget to this materials utilizing UV-curable glue, leading to an ultra-light and sturdy construction that can be utilized for quite a lot of functions.

Versatility, sturdiness and future analysis

Typical photovoltaic photo voltaic cells are fragile, so they’re encased in heavy glass and steel framing. This locations many limitations on the place photo voltaic cells will be put in and deployed. This is the reason there may be renewed curiosity in creating such versatile ultra-thin photo voltaic cells. For instance, earlier this 12 months, Dartmouth researchers developed a brand new flexographic printing course of to deposit perovskite photo voltaic cells on nearly any materials.

MIT researchers examined the sturdiness of the brand new units they developed, and located that the cells retained greater than 90 p.c of their preliminary power-generating capabilities even when the material was rolled and unfold greater than 500 instances. Nevertheless, they nonetheless should be lined with one other materials to guard them from the weather.

Researchers advised indianexpress.com that extra work is required to make these cells extra strong. “We’re creating light-weight packaging know-how that might be versatile and mechanically robust, which can allow us to keep up the present PV format,” mentioned Bulović.

When packaging know-how was developed, researchers envisioned many makes use of for the fabric. For instance, it may be put in on the sails of a ship to offer energy at sea. It can be used with tents and tarps used throughout catastrophe restoration operations, and even with drones to extend their vary.

[ad_2]

Source link