Japanese researchers have developed a method to restore photo voltaic modules with broken busbars and solder ribbons. They declare that the brand new methodology may be carried out on web site, with out eradicating the panels from the row.

A Japanese analysis group has developed a brand new method to restore failures in solder interconnections in photovoltaic panels.

“If there’s a disconnection between busbars and solder ribbons in silicon photo voltaic modules, it’s attainable to restore the defective half on the spot,” the corresponding creator of the analysis, Yu Kawano, mentioned. pv journal. “We have now developed a low-cost know-how to increase the lifetime of photo voltaic cells, permitting them to recuperate their output immediately on the out of doors set up web site, with out disassembling the photo voltaic module or eradicating it from the photo voltaic array .”

The novel methodology makes use of a conveyable induction heating system offered by Japan-based know-how supplier Toray Engineering Co., Ltd. restore solder joints and interconnection failures. “It has a spot diameter of two.0 mm and operates underneath an influence of three.5 kW, a frequency of 900 kHz, and a distance between the system and the PV module of two.0 mm,” the researchers defined.

The workforce examined the induction heating system by making use of it solely to the area with interconnection failures within the broken modules, with the heating time various from 0.1 s to 10.0 s, and mentioned that the heating time of exceeding the ten.0 s threshold could lead to further harm. to the panels.

For the check, scientists used broken and undamaged modules with a again sheet / EVA / Si photo voltaic cells / EVA / cowl glass construction, with dimensions of 145 mm × 145 mm, and collection related to photo voltaic cells with a measurement of 26. mm × 120 mm.

“In line with the consequence, the optimized heating time of two.0 s ends in a extra homogeneous mild all through the module with excessive electroluminescence (EL) depth strains in each horizontal and vertical strains,” they specified. “The very lengthy heating time of 10.0 s degrades the fill issue (FF) worth to 0.765.”

Scientists say the system has confirmed to be efficient in decreasing collection resistance and recovering efficiency in broken panels.

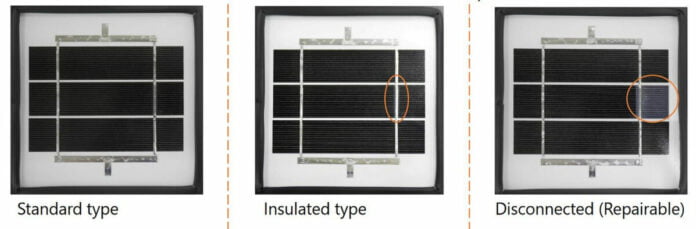

“It’s famous {that a} extra apparent efficiency restoration may be seen utilizing the proposed methodology of repairing the silicon PV module with many failures of solder joints and electrodes, solder, and interconnection ribbons,” they mentioned. “The optimized heating time for the disconnected Si PV module ends in the restoration of the FF worth near that for the usual Si PV module, which is in step with the restoration of EL imaging.”

The brand new method is described within the research “Growth of a restore method for the interconnection of silicon photovoltaic modules utilizing an induction heating system,” printed in Photo voltaic Power. The analysis workforce contains scientists from Ritsumeikan College and Japanese copper wire producer Showa Seisakusho Co., Ltd.

This content material is protected by copyright and is probably not reused. If you wish to cooperate with us and need to reuse a few of our content material, please contact: [email protected].