[ad_1]

Austrian researchers investigated the crack propensity of backsheets manufactured from polypropylene (PP) and concluded that they can be utilized in photo voltaic module manufacturing, in contrast to co-extruded polyamide backsheets, which induced many complications within the PV business previously. As well as, PP backsheets are claimed to have decrease stiffness and better flexibility than their laminated counterparts.

A bunch of researchers led by the Polymer Competence Middle Leoben in Austria investigated the cracking propensity of co-extruded backsheet based mostly on three layers of polypropylene (PP) in an effort to guage their reintroduction within the photo voltaic module manufacturing business.

“For a number of years, we’ve examined co-extruded backsheets based mostly on polypropylene relating to their properties, efficiency and reliability,” stated the lead creator of the analysis, Gernot Oreski, stated. pv journal. “The most important threat for these new backsheet varieties is the incidence of cracks after a number of years of area operation.”

Within the paper “Investigation of the crack propensity of co-extruded polypropylene backsheet movies for photovoltaic modules,” revealed in Photo voltaic Power Supplies and Photo voltaic Cellsscientists do not forget that these backsheets have been used within the business resulting in the so-called “polyamide backsheet catastrophe,” which they are saying refers back to the many defective installations that developed between 2009 and 201.5 in lots of nations with this expertise.

“In my view, it is a actually new thought to make use of co-extruded backsheet, the place every layer has totally different necessities and due to this fact totally different fillers and components,” stated Oreski. “Nevertheless, the selection of the fabric and particularly the fabric qualification was not completed fully. The generally used check protocols beforehand targeted on publicity to single stresses, and due to this fact the issue of long-term habits of polyamide was not revealed, and due to this fact the cracking of the backsheets occurred after just a few years.

“Within the meantime, new check protocols have been developed particularly to problem such backsheet failures, and the solder bump coupon check is one in all them,” he continued. “Sadly, this has led to a reluctance on the a part of the PV business not solely to make use of polyamides, which is comprehensible but additionally to make use of co-extruded backsheet movies basically.”

Teachers defined within the research that co-extruded PP backsheets have decrease stiffness and better flexibility than laminated backsheets. As well as, they famous that PP backsheets confirmed low water vapor transmission charges similar to their PET counterparts, however had excessive permeation charges for oxygen and acetic acid.

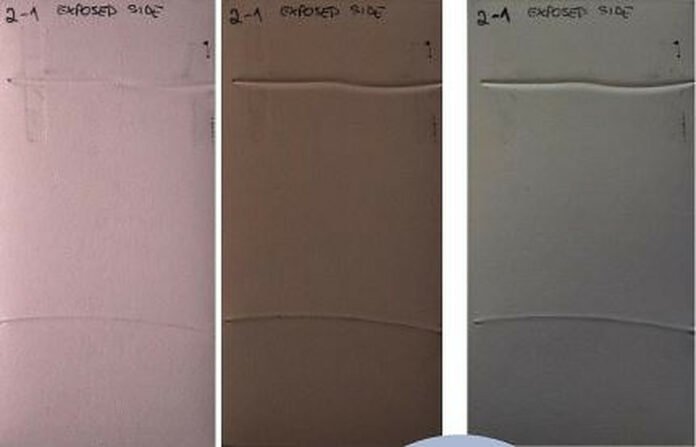

With an ordinary encapsulant, the scientists made check specimens, which they known as solder bump coupons, and subjected them to accelerated growing old assessments along with reference laminated backsheets.

They examined 5 totally different specimens: a co-extruded backsheet based mostly on PP; a co-extruded backsheet based mostly on polyamide (PA); a laminated backsheet based mostly on polyethylene (PE), polyethylene terephthalate (PET), and polyvinylidene difluoride (PVDF); a laminated backsheet based mostly on polyvinyl fluoride (PVF) and PET; and a laminated backsheet based mostly on fluorinated coating (fc), PET, and PVDF.

The Austrian group then uncovered the specimens, after the casket, to five cycles consisting of the stresses of every pepper.

The check confirmed that solely the second and third backsheet varieties listed confirmed extreme cracking. The opposite three varieties, quite the opposite, don’t present any cracks or outer layer embrittlement.

“The outcomes of this research verify beforehand revealed outcomes on the long-term stability of co-extruded backsheets based mostly on PP, which present a superb stability to temperature, humidity and UV,” the group stated referring to the distinctive group of the primary backsheet kind. “The general co-extruded PP back-sheet exhibits nice potential to be a sound alternative for the usual PET-based backsheet in PV modules.”

The analysis group additionally consists of scientists from the Austrian Analysis Institute for Chemistry and Expertise, Silicon Austria Labs, Kioto Photo voltaic, and Borealis Polyolefine GmbH.

“Co-extrusion permits the variation of the backsheet precisely to the necessities required for particular situations, as a result of the method itself is extra versatile than the lamination course of,” stated Oreski, referring to the true prospects of co-extruded backsheets to re-enter the PV business by adopting the PP materials.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].

[ad_2]

Source link