Scientists from Germany’s Fraunhofer ISE and US panel maker Solaria utilized thermal laser separation and post-metallization passivated edge expertise to tunnel oxide passivated contact (TOPCon) cell manufacturing. They produce shingle PV gadgets which can be extra environment friendly than cells constructed utilizing typical laser scribing and mechanical cleaving strategies.

Scientists from Germany Fraunhofer Institute for Photo voltaic Power Techniques ISE and US-based photo voltaic panel makers Solaria has developed a photo voltaic cell based mostly on TOPCon expertise and shingle design.

“To the very best of our information, that is the primary publication coping with TOPCon shingle photo voltaic cells separated by thermal laser separation (TLS) and edge-passivated by passivated edge expertise (PET),” stated researcher Elmar Lohmüller. pv journal. “PET is a proprietary growth of Fraunhofer ISE, to deal with the chopping losses of present half-cut, third-cut, or shingle photo voltaic cells, by easy, high-throughput post-processing of singulated cells.”

Fraunhofer ISE filed a patent software again in 2018 and presents a pattern of the expertise for companions. Solaria was one of many first business companions to check post-metallization PET in TOPCon shingle photo voltaic cells.

“The PET methodology can meet an vital want within the business – to scale back the lack of effectivity incurred in chopping the cell and do it in an efficient means,” Ricky Dunbar, a spokesman for Solaria, stated. . pv journal. “Our cooperation with Fraunhofer ISE reveals that PET can successfully cut back these losses for TOPCon shingle cells with a promising throughput.”

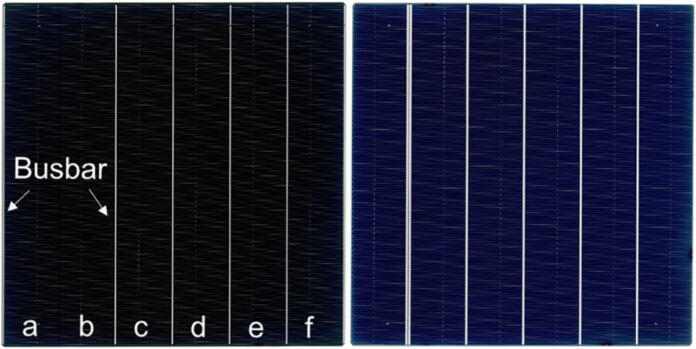

The proposed manufacturing course of makes use of thermal laser separation (TLS) as a substitute of typical laser scribing and mechanical cleaving (LSMC) for cell singulation. TLS requires solely a brief preliminary laser scribe with a cleave laser and a water-air aerosol jet to create an initiating crack that may propagate by the wafer in any path.

“This ends in cuts with smoother edges,” the scientists defined, noting that the TLS was produced by the microDICE laser system produced by 3D-Micromac in Germany.

“The TLS course of optimized on this work yields as much as 0.2% extra environment friendly shingle cells straight after separation in comparison with shingle cells remoted by LSMC,” the teachers stated. , which states that the cell based mostly on TLS achieves an influence conversion effectivity of twenty-two.0% “It has been proven that TLS may be carried out in such a means that there is no such thing as a deterioration within the high quality of the floor passivation that happens within the surroundings on the dividing line.”

The analysis group offered its findings in “TOPCon shingle photo voltaic cells: Thermal laser separation and passivated edge expertise,” not too long ago revealed in Advances in Photovoltaics.

“Whereas we’re nonetheless within the growth part of an industrial PET instrument, legitimate information for the yield ratios of the 2 strategies for a dependable price calculation should not but obtainable sufficient, ” stated Lohmüller. “Nevertheless, PET will add a step to the method, which to our present information can simply be modified to in the present day’s throughput calls for, thus the demonstrated effectivity achieve has loads of potential to compensate for the extra price.”

This content material is protected by copyright and is probably not reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: [email protected].